When selecting a load cell for your weighing application, capacity and accuracy usually get the most attention. However, the material composition of your load cell—typically either alloy steel or stainless steel—is equally critical for long-term performance. The wrong material choice can lead to premature corrosion, zero drift, and catastrophic failure within months, while the right choice ensures decades of reliable service.

This comprehensive guide compares alloy steel and stainless steel load cells across different environments, from humid Southeast Asian rice mills to frozen Nordic fishing vessels. Whether you're working with food-grade hygiene requirements, offshore oil platforms, or standard warehouse applications, understanding material properties will save you thousands in replacement costs and prevent dangerous equipment failures.

Understanding Load Cell Material Basics

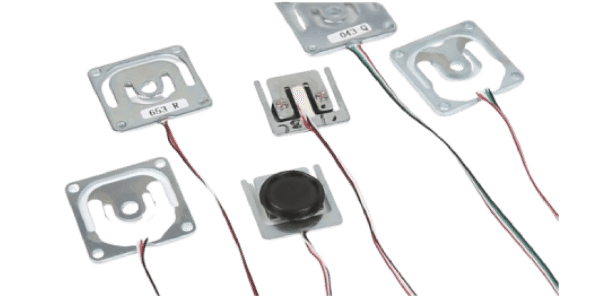

Load cells are fundamentally precision instruments where the metal body itself acts as the spring element. The material must exhibit excellent elastic properties, fatigue resistance, and environmental stability. Two materials dominate the industry: alloy steel (typically tool steel or aluminum-coated variants) and stainless steel (primarily 17-4PH precipitation-hardening grade).

The choice between these materials affects not just corrosion resistance, but also cost, weight, magnetic properties, and temperature coefficient. Making an informed decision requires understanding both the metallurgical differences and your specific operational environment.

Alloy Steel Load Cells: Properties and Applications

Alloy steel load cells are manufactured from high-strength carbon steels, typically 40CrNiMoA (Chinese designation) or similar tool steel grades. These materials offer excellent elastic modulus and fatigue life when properly treated.

Advantages of Alloy Steel

Cost-Effectiveness: Alloy steel load cells cost 30-50% less than stainless equivalents, making them attractive for high-volume applications where budgets are constrained. A standard 1000kg alloy steel shear beam might cost $80-120 versus $180-250 for stainless steel.

High Elastic Modulus: Alloy steel provides excellent spring characteristics with minimal hysteresis, making it ideal for high-precision laboratory balances and standard industrial scales.

Strength: Properly heat-treated alloy steel achieves tensile strengths exceeding 1700 MPa, allowing compact designs for heavy-capacity applications (truck scales, rail weighbridges).

Limitations and Vulnerabilities

Corrosion Susceptibility: The primary weakness. Without protective coatings, alloy steel rusts rapidly in humid environments. Even minor surface rust creates stress concentration points that initiate fatigue cracks.

Coating Dependency: Most alloy steel load cells rely on nickel plating, epoxy painting, or zinc coatings for protection. Once these barriers are compromised—through scratches, chemical exposure, or wear—corrosion accelerates.

Not Suitable for Food Contact: Regulations in the EU (EC 1935/2004), USA (FDA 21 CFR), and Australia (FSANZ) prohibit nickel-plated alloy steel in direct food contact applications due to contamination risks.

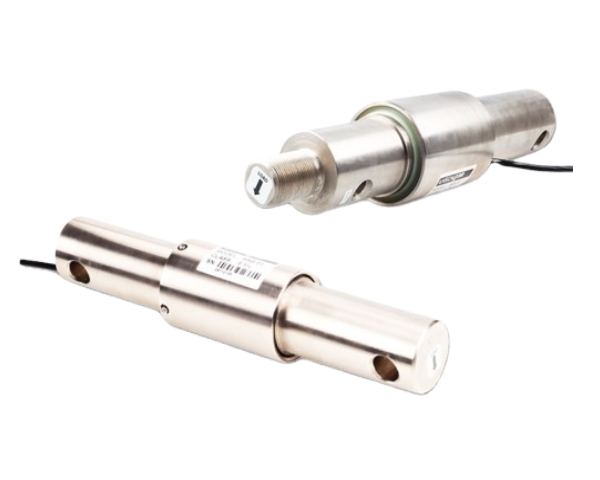

Stainless Steel Load Cells: The Corrosion-Resistant Standard

Stainless steel load cells typically use 17-4PH (precipitation-hardening martensitic) or 304/316 austenitic grades. 17-4PH dominates precision load cell manufacturing due to its ability to achieve high strength (H900 condition: 1310 MPa yield strength) while maintaining stainless properties.

Advantages of Stainless Steel

Superior Corrosion Resistance: The chromium oxide layer (Cr₂O₃) provides passive protection against moisture, most acids, and salt exposure. 316L grade adds molybdenum for enhanced chloride resistance—critical for marine and coastal applications.

Hygiene and Cleanability: Smooth stainless surfaces meet sanitary standards for pharmaceutical, dairy, meat processing, and beverage industries. Resistant to high-pressure washdown with caustic cleaners.

Temperature Performance: Stainless steel maintains mechanical properties across wider temperature ranges (-60°C to +200°C for standard grades, up to +300°C for high-temperature variants).

Long-Term Value: While initial cost is higher, stainless load cells often last 2-3x longer in harsh environments, delivering lower total cost of ownership (TCO).

Considerations and Costs

Higher Initial Investment: Material costs and machining complexity result in 2-3x price premiums over alloy steel. Specialized 17-4PH stock requires precise heat treatment (solution annealing followed by aging).

Magnetic Properties: Martensitic stainless steels (17-4PH) are magnetic, which may interfere with certain sensitive applications. Austenitic 316L is non-magnetic but generally lower strength.

Galvanic Corrosion Risk: When mounted to mild steel structures in wet environments, stainless steel can accelerate corrosion of the mating material. Isolate using insulating washers or pads.

Regional Environmental Challenges and Material Selection

Coastal and Marine Environments (Australia, Gulf Coast USA, Nordic Fjords)

The Challenge: Salt spray creates aggressive chloride attack. Standard alloy steel shows rust within weeks. Even inland areas within 50km of coasts experience accelerated corrosion.

Recommended Material: 316L stainless steel (marine grade) with IP68/IP69K sealing. The molybdenum content in 316L resists pitting corrosion from salt crystals.

Regional Examples: Australian lobster processing facilities along the Great Ocean Road require 316L load cells for weighing catches on wet docks. Norwegian salmon farms use submersible stainless load cells for underwater net monitoring. Florida phosphate mining operations specify 316L for fertilizer handling despite higher costs.

Food Processing and Hygiene-Critical Applications (Europe, North America)

The Challenge: Daily washdown with high-pressure hot water, caustic sanitizers (NaOH, peracetic acid), and strict microbiological requirements.

Recommended Material: 17-4PH stainless steel with polished surfaces (Ra < 0.8μm). Electropolished finishes preferred for pharmaceutical applications to prevent bacterial adhesion.

Regulatory Context: German dairy operations (Schleswig-Holstein) require EHEDG-compliant stainless load cells for tank weighing. Wisconsin cheese plants use 17-4PH cells with hermetically sealed cables to prevent moisture ingress during CIP (Clean-in-Place) cycles.

Chemical and Petrochemical Industries (Middle East, Houston, Rotterdam)

The Challenge: Exposure to hydrocarbons, sulfur compounds, and extreme temperatures (ambient 50°C+ in UAE, process temperatures up to 120°C).

Recommended Material: 17-4PH with specialized coatings for chemical resistance. For offshore platforms (Saudi Aramco, ADNOC), specify NACE MR0175/ISO 15156 compliant materials for sour gas environments.

Regional Note: Middle Eastern refineries often specify 17-4PH H1150 condition for better toughness and stress corrosion cracking resistance compared to standard H900. Alloy steel is prohibited in zones with hydrogen sulfide (H₂S) exposure due to sulfide stress cracking risks.

High-Humidity Agricultural Zones (Southeast Asia, Brazil, Southern US)

The Challenge: Year-round humidity (80-95% RH), monsoon rains, and organic matter decomposition creating acidic environments (poultry farms, palm oil mills).

Recommended Material: IP68-rated 17-4PH stainless steel. While alloy steel with good epoxy coating can last 3-5 years in these conditions, stainless provides 10+ year lifespans with minimal maintenance.

Economic Reality: Thai rice mill operators initially choose alloy steel for cost savings but face replacement every 2-3 years during monsoon season. ROI calculations favor stainless steel when labor costs for replacement are factored.

Freezing and Cryogenic Environments (Canada, Nordic Countries, Russia)

The Challenge: -40°C temperatures embrittle some steels, while thermal cycling causes condensation and ice formation.

Recommended Material: 17-4PH maintains toughness at cryogenic temperatures (Charpy V-notch > 20J at -40°C). Alloy steel becomes brittle below -20°C unless specially treated.

Application Examples: Canadian grain elevators use stainless load cells to prevent winter corrosion from condensation during temperature swings. Russian LNG facilities specify cryogenic-rated stainless load cells for liquid natural gas weighing (-162°C), though these require specialized 304L or Inconel variants rather than standard 17-4PH.

Standard Indoor Industrial (Warehouses, Manufacturing)

The Challenge: Controlled environments with occasional humidity but no chemical exposure or washdown requirements.

Recommended Material: Nickel-plated alloy steel offers optimal value. In climate-controlled European logistics centers or US distribution warehouses, alloy steel load cells on pallet scales provide 10-15 year service lives when protected from physical damage.

Performance Comparison Matrix

Corrosion Resistance:

- Alloy Steel: Poor (requires coating)

- 17-4PH Stainless: Excellent

- 316L Stainless: Superior (marine environments)

Cost (Relative):

- Alloy Steel: 1.0x (baseline)

- 17-4PH Stainless: 2.0-2.5x

- 316L Stainless: 2.5-3.5x

Magnetic Properties:

- Alloy Steel: Magnetic

- 17-4PH: Magnetic (martensitic)

- 316L: Non-magnetic (austenitic)

Temperature Range:

- Alloy Steel: -20°C to +80°C

- 17-4PH: -60°C to +200°C

- 316L: -200°C to +400°C

Suitability for Food/Pharma:

- Alloy Steel: Not permitted

- 17-4PH: Standard

- 316L: Premium (high chloride foods)

Cost-Benefit Analysis: When to Choose Which

Choose Alloy Steel When:

• Budget constraints are severe (30-50% cost savings)

• Environment is climate-controlled and dry

• Application is temporary or portable

• Weight is being measured, not used for trade/legal metrology

• Located in arid regions (Arizona, Sahara, Central Australia) away from coasts

Choose 17-4PH Stainless Steel When:

• Washdown cleaning is required (food, pharma, chemical)

• Outdoor exposure with rain/snow

• High-humidity climates (tropics, coastal)

• Heavy industrial with airborne corrosives

• Long-term installation where maintenance access is difficult

• Legal-for-trade applications requiring 10+ year certification stability

Choose 316L Stainless Steel When:

• Marine/offshore salt spray exposure

• Chloride-rich environments (swimming pools, coastal aquaculture)

• Aggressive chemical processing (bleach, acids)

• Submersible applications (underwater weighing)

• Maximum lifespan required (15-20 years)

Maintenance Implications by Material

Alloy Steel Maintenance:

Requires quarterly inspection of protective coatings. Touch up scratches immediately with zinc-rich paint or replacement of plating. Typical lifespan in moderate outdoor environments: 3-7 years before corrosion affects accuracy.

Stainless Steel Maintenance:

Annual inspection sufficient. Clean with mild detergent to remove deposits that could cause crevice corrosion. Inspect cable entry seals (IP rating integrity more critical than material). Typical lifespan: 10-20 years depending on grade and environment.

FAQs: Load Cell Material Selection

Is alloy steel or stainless steel better for load cells?

For dry indoor applications, alloy steel offers better value. For outdoor, washdown, or corrosive environments, stainless steel is essential despite higher initial cost. Stainless steel provides 3-4x longer service life in harsh conditions.

What is 17-4PH stainless steel in load cells?

17-4PH is a precipitation-hardening martensitic stainless steel offering high strength (up to 1310 MPa) combined with corrosion resistance. It's the industry standard for high-precision stainless load cells, providing better elasticity than 304/316 grades while maintaining rust resistance.

Can alloy steel load cells be used outdoors?

Only with rigorous protection. Nickel-plated alloy steel can survive 2-3 years outdoors in temperate climates, but will fail within months in coastal or tropical environments. Specify IP68-rated alloy steel and plan for replacement every 3-5 years.

Why are stainless steel load cells more expensive?

Raw material costs for 17-4PH are 3-4x higher than tool steel. Additionally, machining stainless is slower (reducing tool life), and heat treatment requires precise temperature control (solution treating at 1040°C followed by aging at 480-620°C).

What load cell material is required for food grade applications?

FDA, EU 1935/2004, and FSANZ regulations require stainless steel (304 or 316) for food contact surfaces. 17-4PH is acceptable for non-contact weighing (tank mounts), while 316L is preferred for high-salinity foods (pickles, brined meats) or marine food processing.

Do stainless steel load cells need to be grounded differently?

Yes. Stainless steel's lower electrical conductivity compared to alloy steel requires ensuring grounding straps or proper shielding to prevent EMI interference. In explosive atmospheres (ATEX zones), special grounding considerations apply to prevent static buildup.

How do I prevent galvanic corrosion with stainless load cells?

When mounting stainless load cells to mild steel structures, use insulating washers (PTFE or nylon) and isolating pads to break the electrical circuit. This prevents the stainless steel from acting as a cathode and accelerating rust on the structure.

What is the best load cell material for saltwater environments?

316L stainless steel (marine grade) is mandatory for saltwater exposure. 17-4PH is insufficient for prolonged saltwater immersion. Specify duplex 2205 stainless or titanium for extreme marine submersion (offshore aquaculture cages).

Installation Best Practices by Material

For Alloy Steel:

• Inspect immediately upon delivery for coating damage

• Avoid scratching during installation (use soft slings, not chains)

• Apply corrosion inhibitor spray to terminal cavities in humid climates

• Do Not use in areas with cyclic condensation without additional protection

For Stainless Steel:

• Clean with alcohol before installation to remove machining oils

• Ensure cable glands are properly torqued (IP rating maintenance)

• Use anti-seize compound on threads to prevent galling

• Isolate from dissimilar metals to prevent galvanic corrosion

Regional Certification and Standards Impact

European Union (CE/OIML):

MID (Measuring Instruments Directive) requires material stability over the certification period. Stainless steel is effectively mandatory for outdoor legal-for-trade applications in maritime climates (Netherlands, UK, Norway).

United States (NTEP):

While NTEP doesn't specify materials, Handbook 44 requires devices to maintain accuracy despite environmental exposure. In Florida and Gulf Coast states, stainless steel is effectively required for outdoor truck scales to pass type evaluation.

Asia-Pacific:

Chinese GB/T standards and Japanese JIS mark emphasize corrosion resistance for tropical climates. Singapore's HSA (Health Sciences Authority) mandates 316L for pharmaceutical manufacturing equipment.

Conclusion: Material Selection for Long-Term Success

The choice between alloy steel and stainless steel load cells transcends initial purchase price. It represents a strategic decision about operational reliability, maintenance burden, and compliance risk.

Select alloy steel for cost-sensitive, climate-controlled indoor applications where replacement every 5-7 years is acceptable. Choose 17-4PH stainless steel for industrial washdown, outdoor exposure, and food-grade requirements. Specify 316L only when facing marine environments or extreme chemical exposure.

For multinational operations, standardizing on 17-4PH stainless steel across all facilities—regardless of local climate—often proves most economical by simplifying spare parts inventory and maintenance training, while ensuring any equipment can be redeployed to harsher environments without material compatibility concerns.

Remember: a failed load cell doesn't just mean replacement cost—it means production downtime, potential safety hazards, and lost revenue. When weighing the 2x price differential between alloy and stainless steel, factor in the total lifecycle cost and operational criticality. In most cases, stainless steel proves the wiser investment.

Need material specification guidance for your specific region? Contact our engineering team for environment-specific recommendations for your load cell application.